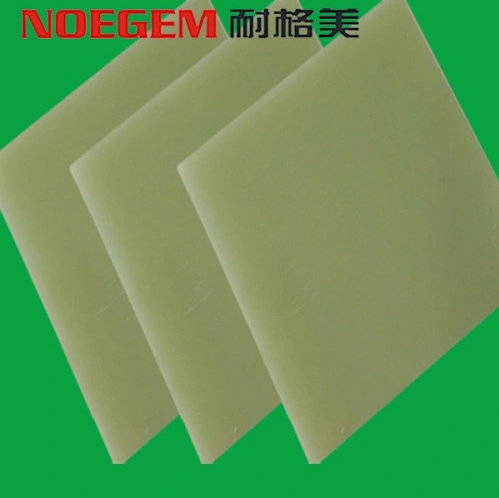

FR4 Glass Fiber Plastic Sheet is a widely used material in various industries, especially in electronics, automotive, aerospace, and more. Understanding its manufacturing process and material composition is crucial for both producers and users. This article provides a comprehensive overview of the manufacturing process and material composition of FR4 Glass Fiber plastic sheets. FR4 glass fiber plastic sheet, also known as fiberglass reinforced epoxy laminate, is a versatile material renowned for its excellent electrical insulation properties, mechanical strength, and chemical resistance. Its widespread use in electronics, automotive, and other industries necessitates a thorough understanding of its manufacturing process and material composition.

Manufacturing Process

The manufacturing process of FR4 glass fiber plastic sheets involves several key steps:

1.Resin Preparation

The process begins with the preparation of the epoxy resin, which serves as the matrix for the composite material. The resin is typically a thermosetting polymer that provides mechanical strength and adhesion properties.

2.Glass Fiber Impregnation

Next, the glass fibers, usually in the form of woven or non-woven mats, are impregnated with the resin. This impregnation ensures uniform distribution of the resin throughout the fiber matrix, enhancing the material's strength and stiffness.

3.Layer Stacking

The impregnated glass fiber sheets are stacked together to form a laminate structure. Depending on the desired thickness and properties of the final product, multiple layers of impregnated fiber sheets may be stacked.

4.Curing

The stacked laminate structure undergoes a curing process, typically through heat and pressure application. This process initiates the cross-linking reactions in the epoxy resin, transforming it from a liquid to a solid state and bonding the glass fibers together.

5.Cutting and Finishing

Once cured, the laminate sheets are cut to the desired dimensions and undergo finishing processes such as surface grinding or polishing to achieve the required surface smoothness and thickness tolerance.

Material Composition

The material composition of FR4 glass fiber plastic sheets primarily consists of:

1.Epoxy Resin

The epoxy resin serves as the matrix material, providing mechanical strength, adhesion, and chemical resistance to the composite.

2.Glass Fibers

The reinforcing phase of FR4 sheets comprises glass fibers, which are typically composed of silica-based materials such as fiberglass. These fibers impart excellent mechanical properties such as tensile strength, stiffness, and impact resistance to the composite material.

3.Additives and Fillers

Various additives and fillers may be incorporated into the resin matrix to enhance specific properties of the FR4 sheets, such as flame retardancy, thermal conductivity, or UV resistance.

FR4 glass fiber plastic sheets are essential materials in numerous industries due to their exceptional mechanical, electrical, and chemical properties. Understanding the manufacturing process and material composition of FR4 sheets is crucial for ensuring the quality and performance of the final products. Continued research and development in this field are essential for further improving the properties and applications of FR4 glass fiber plastic sheets.